Now ATEX certified

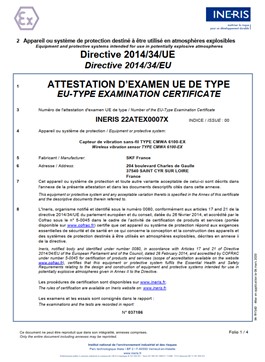

Wireless IMx-1 sensors

Safe use of IMx-1 sensors in hazardous environments

The SKF Wireless IMx-1 sensor has obtained the ATEX certification. Thanks to these ATEX certificates, this successful wireless IMx-1 sensor can now also be introduced in the Oil & Gas and Petro Chemical industry, where ATEX Zone 1 / Zone 2 product certification related to safe use in hazardous environment is required.

Interesting for Energy and Chemical Industry

Cost effectiveness

Mounting vibration sensors can be very time consuming and costly business. Much of this is due to the time needed to properly lay all the sensor cables. Without sensor cables the speed and complexity of sensor mounting is drastically improved. This makes wireless sensors financially interesting for much equipment that was previously left out of scope.

Safety aspect

People are working on the live, rotating equipment. Especially in an ATEX environment you want to minimize the number of personnel walking around the plant. Fixed sensors allow you to gather your data without the need to get near the machines. The higher data density largely compensates for the absents of a physical inspection.

Applicable for hard-to-reach machines/measuring points

Guards and fences has brought a lot when it comes to worker safety, but these barriers can make an inspection or manual vibration measurement impossible. The IMx-1, easy to install wireless sensors help you look over the fence and give you data that is currently out of reach.

Staff shortage

An increasing hunger for data forces you to measure more equipment and put a higher strain on your often aging and understaffed condition monitoring department or contractor. Buy them time by mounting wireless sensors and avoid unnecessary travel or walking great distances through the plant gathering data.

Product Maturity

SKF has been working with vibration analyses on bearings since the early 1950's. Commercially SKF has been selling condition monitoring hardware and software since the 1980's. Although much has changed over the years SKF's history and knowledge can be found in the new IMx-1 wireless sensor. Allowing you to monitor overall values of velocity, acceleration, envelope and temperature and analyse FFT spectra in our trusted @ptitude Observer software.

Cybersecurity

SKF works on a continuous basis to protect customer information (data). The IMx-1 operates with a dedicated Wireless Mesh network and GPRS data Sim card, with no local customer network interaction.

Amazon Web Services (AWS) is responsible for the physical security of the datacentre, and the security of the cloud. SKF is responsible for security in the cloud, for example operating systems, applications and configuration. SKF is also responsible for keeping software updated and patched.

Customers have limited responsibilities for the security in SKF Cloud. However, customers should keep the following in mind when it comes to information security.

-

To protect login information

-

To handle downloaded data securely

-

To protect hardware and sensors from unauthorised access.

-

To inform SKF if staff quit so that access can be removed.

IMx-1 Sensor

Hardware

-

Sensor to gateway communication; Encrypted AES (128 Bit)

-

Gateway/App to host network communication; Encrypted TLS (4096 bit)

-

Certificates traceable to SKF Wi-Fi: EAP TLS, TTLS and PEAP.

-

Randomised passwords – unique for each gateway Hashing of sensitive configuration data

Item numbers

-

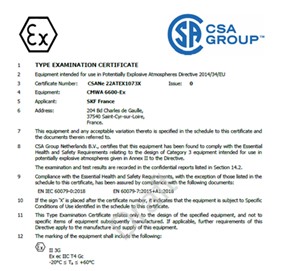

CMWA 6100-EX, Wireless IMx-1 sensor – ATEX zone 1 certified

-

CMWA 6600-EX, Gateway IMx-1 – ATEX zone 2 certified

Talk to us about automating predictive maintenance for reliable rotation