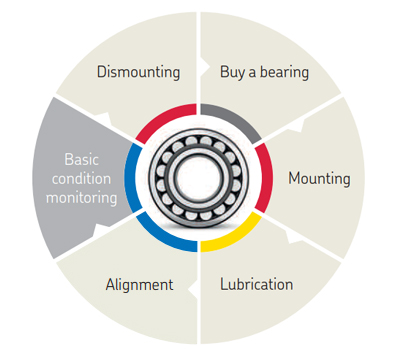

| Bearing Life Cycle | Buy a bearing | Mounting | Lubrication | Alignment | Basic Condition Monitoring | Dismounting

| Bearing Life Cycle | Buy a bearing | Mounting | Lubrication | Alignment | Basic Condition Monitoring | Dismounting

Basic Condition Monitoring

To help ensure long bearing service life, it is important to determine the condition of machinery and bearings while in operation. With a good predictive maintenance program, your maintenance staff will no longer be in the firefighting mode, machine downtime will be reduced and overall maintenance costs will decrease. To help you achieve the maximum service life from your bearings, SKF has developed a wide range of instruments for analysing the critical operating conditions which have an impact on bearing and machine performance.

Basic Condition Monitoring

To help ensure long bearing service life, it is important to determine the condition of machinery and bearings while in operation. With a good predictive maintenance program, your maintenance staff will no longer be in the firefighting mode, machine downtime will be reduced and overall maintenance costs will decrease. To help you achieve the maximum service life from your bearings, SKF has developed a wide range of instruments for analysing the critical operating conditions.

Maintenance concepts: Run to failure, Preventive maintenance and Predictive maintenance

SKF has developed a comprehensive range of basic condition monitoring tools suitable for Operator Driven Reliability (ODR) and maintenance technicians. Under ODR, some maintenance practices are owned, managed, and performed by operators. Often, the operators are the persons best equipped for basic inspection activities, as they know their part of the plant very well. They are typically sensitive to minor changes in sounds and vibrations that may not be apparent to someone lacking their frontline experience.

Subsequently, minor defects can be corrected quickly, as the operator can undertake simple adjustment and repair tasks. Maintenance technicians also have need for basic condition monitoring tools. If, for example, abnormal vibrations are detected or if an operator reports an abnormal running condition, then the technician can often use some basic condition monitoring tools to detect the root cause for further evaluation.

Maintenance concepts: Run to failure, Preventive maintenance and Predictive maintenance

SKF has developed a comprehensive range of basic condition monitoring tools suitable for Operator Driven Reliability (ODR) and maintenance technicians. Under ODR, some maintenance practices are owned, managed and performed by operators, as they often know their part of the plant very well. They are typically sensitive to minor changes in sounds and vibrations that may not be apparent to someone lacking their frontline experience. Subsequently, minor defects can be corrected quickly, as the operator can undertake simple adjustment and repair tasks.

If, for example, an operator reports abnormal vibrations or running conditions, the maintenance technician might need only some basic condition monitoring tools to detect the root cause for further evaluation.

SKF QuickCollect sensor

Machine data. Collect it, interpret it, benefit from it. Learn how SKF QuickCollect connects via apps to mobile devices and the cloud. The SKF QuickCollect sensor (play video) makes machine data collection simpler and cost-effective. This sensor is combined with mobile apps that reduce the complexity of data collection and analysis so that you can detect machine issues before they cause failures.

SKF ProCollect

Upgrade to ProCollect and enhance your maintenance program. Empower your operations team, create, schedule and execute manual inspection, lubrication routes, gain deeper insights into your machinery, save and share data to the cloud, gain access to easy-to-understand dashboards, and connect to SKF experts. All for a fixed fee, reducing the need for significant start-up investment.

This is how it works

Managing your operation and maintenance is a round-the-clock responsibility. Unplanned asset downtime is a problem for everyone involved. Knowing the status of your assets is critical, and should be as easy as it can be. Watch the video and see for yourself.

This is how it works

Managing your operation and maintenance is a round-the-clock responsibility. Unplanned asset downtime is a problem for everyone involved. Knowing the status of your assets is critical, and should be as easy as it can be. Watch the video and see for yourself.

SKF QuickCollect sensor

Machine data. Collect it, interpret it, benefit from it. Learn how SKF QuickCollect connects via apps to mobile devices and the cloud. The SKF QuickCollect sensor (play video) makes machine data collection simpler and more cost-effective. This sensor is combined with mobile apps that reduce the complexity of data collection and analysis so that you can detect machine issues before they cause failures.

SKF ProCollect

Upgrade to ProCollect and enhance your maintenance program. Empower your operations team, create, schedule and execute manual inspection, lubrication routes, gain deeper insights into your machinery, save and share data to the cloud, gain access to easy-to-understand dashboards, and connect to SKF expertise whenever you need it. All for a fixed fee, reducing the need for significant start-up investment.

Infrared thermometer TKTL series

SKF offers a wide range of portable, lightweight and easy-to-use infrared thermometers for thermal inspections. These portable tools help you to detect temperature differences in technical and non-technical applications, this in order to perceive information on abnormalities in operating.

Electrical discharge detector TKED 1

Electrical discharges are a result of motor shaft voltages discharging to earth through the bearing, causing electrical erosion, lubricant degradation and ultimately bearing failure. An electrical discharge detector can help detect the presence of electrical discharge currents, allowing remedial action to be taken.

SKF Stroboscope TKRS series

SKF Stroboscope TKRS 41 is a high performance stroboscope for visually inspecting running machines and for determining the machine speed.

The built-in laser speed measurement and simple controls help users to quickly set the correct flash rate and obtain clear “frozen” images for inspection.

Get in touch with the team to learn more about the benefits of how to prevent premature bearing failure.

Infrared thermometer TKTL series

SKF offers a wide range of portable, lightweight and easy-to-use infrared thermometers for thermal inspections. These portable tools help you to detect temperature differences in technical and non-technical applications, this in order to perceive information on abnormalities in operating.

Electrical discharge detector TKED 1

Electrical discharges are a result of motor shaft voltages discharging to earth through the bearing, causing electrical erosion, lubricant degradation and ultimately bearing failure. An electrical discharge detector can help detect the presence of electrical discharge currents, allowing remedial action to be taken.

SKF Stroboscope TKRS series

SKF Stroboscope TKRS 41 is a high performance stroboscope for visually inspecting running machines and for determining the machine speed.

The built-in laser speed measurement and simple controls help users to quickly set the correct flash rate and obtain clear “frozen” images for inspection.

Get in touch with the team to learn more about the benefits of how to prevent premature bearing failure.