| Bearing Life Cycle | Buy a bearing | Mounting | Lubrication | Alignment | Basic Condition Monitoring | Dismounting

| Bearing Life Cycle | Buy a bearing | Mounting | Lubrication | Alignment | Basic Condition Monitoring | Dismounting

Lubrication matters. But do you know how much?

Lubrication matters. But do you know how much?

Correct bearing lubrication is an essential step in reaching the bearing’s service lifetime. 50% of premature bearing failure is the result of poor lubrication and/or contamination. Incorrect lubrication will cause both high maintenance costs and health & safety issues due to slippery work floors or hard-to-reach places.

It is important to select grease suitable for the bearing’s application, and to apply the correct quantity before commissioning the bearing.

During operation, the bearing will require periodic relubrication. The right quantity of the right grease applied at the right intervals is essential to achieving optimum bearing performance and maximum service life.

Using manual relubrication methods is common practice; however, continuous relubrication offers many advantages. Continuous relubrication can be performed by using automatic lubricators, which provide a more consistent, accurate and contamination-free grease supply.

Correct bearing lubrication is essential in reaching the bearing’s service lifetime. 50% of premature bearing failure is the result of contamination and/or poor lubrication and will cause both high maintenance costs and health & safety issues due to slippery work floors or hard-to-reach places.

It is important to select grease suitable for the bearing’s application and to apply the correct quantity before commissioning the bearing. The bearing will require periodic relubrication during operation. The right quantity of the right grease applied at the right intervals is essential to achieving optimum bearing performance and maximum service life.

SKF SYSTEM 24 - single point automatic lubricator

Performing manual lubrication tasks can be challenging due to the vast number of lubrication points throughout a factory. Also, most of these points have varying lubrication requirements. Utilising SKF SYSTEM 24 single point automatic lubricators is one solution that can improve worker safety and increase machine reliability. For more information click here to download our Automatic Lubricators brochure.

SKF DialSet

SKF DialSet has been designed to help you to set up your SKF automatic lubricators. After selecting the criteria and grease appropriate for your application, the program provides you with the correct settings for your SKF automatic lubricators. It also provides a quick and simple tool for relubrication intervals and quantity calculations. Available online or mobile app.

SKF SYSTEM 24

Performing manual lubrication tasks can be challenging due to the vast number of lubrication points with varying lubrication requirements throughout a factory. SKF SYSTEM 24 single point automatic lubricators can improve worker safety and increase machine reliability.

SKF DialSet

After selecting the criteria and grease appropriate for your application, SKF DialSet provides you with the correct settings for your SKF automatic lubricators, relubrication intervals and quantity calculations.

Available online or mobile app

SKF LubeSelect

Selecting a suitable grease for a particular bearing is a crucial step if the bearing is to meet design expectations in its application. Use the SKF LubeSelect to select the right lubricant for your application. Go to LubeSelect

SKF Lubrication Planner

A proper lubrication plan can help avoid unplanned machine downtime. With SKF Lubrication Planner you can develop and follow up your lubrication plans.

Go to Lubrication Planner

SKF LubeSelect

Selecting a suitable grease for a particular bearing is a crucial step if the bearing is to meet design expectations in its application. Use the SKF LubeSelect to select the right lubricant for your application. Go to LubeSelect

SKF Lubrication Planner

A proper lubrication plan can help you to avoid unplanned machine downtime. With SKF Lubrication Planner you can develop and follow up your lubrication plan. Go to Lubrication Planner

Battery Driven Grease Gun

Developed to maximise efficiency, the SKF Battery Driven Grease Gun TLGB 20 includes an integrated grease meter to help prevent over- and under-lubrication.

Suitable for a variety of manual lubrication tasks, the TLGB 20 can be used to lubricate bearings and machines in industrial and manufacturing environments.

Battery Driven Grease Gun

Developed to maximise efficiency, the SKF Battery Driven Grease Gun TLGB 20 includes an integrated grease meter to help prevent over- and under-lubrication.

Suitable for a variety of manual lubrication tasks, the TLGB 20 can be used to lubricate bearings and machines in industrial and manufacturing environments.

SKF Grease meter LAGM 1000E

The amount delivered per stroke by grease guns depends on many variables. It is generally difficult to supply an accurate quantity of grease when manually lubricating bearings. The right amount of grease, however, is critical for the bearings’ service life, as over- or under greasing can result in machine breakdown.

SKF Grease Meter LAGM 1000E

The amount delivered per stroke by grease guns depends on many variables. It is generally difficult to supply an accurate quantity of grease when manually lubricating bearings. The right amount of grease, however, is critical for the bearings’ service life, as over- or under greasing can result in machine breakdown.

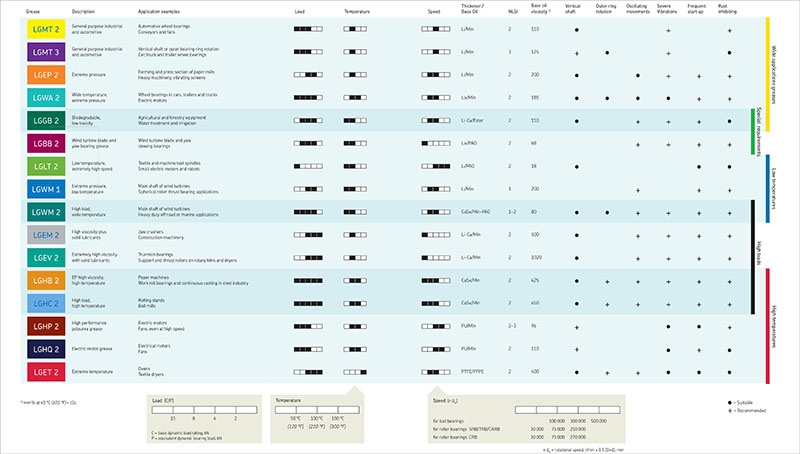

Grease Selection Chart

Select the right SKF grease for your application with the grease selection chart, available format: PDF 50 x 70 cm.

Grease selection chart

Select the right SKF grease for your application with the grease selection chart.

Available format: PDF 50 x 70 cm

Get in touch with the team to learn more about the benefits of how to prevent premature bearing failure.

Get in touch with the team to learn more about the benefits of how to prevent premature bearing failure.